Guo Jiaohe1 Liu Shuhua1 Ning Aimin1 Wang Tao2 Li Hongqing2 Yao Dehong2

(1.China Petroleum and Chemical Corporation Fushun Research Institute of Petroleum and Petrochemicals, Fushun 113001)

(2.Shandong Xianyuann Chemical Technology Co., Ltd. Zibo 255400)

Abstract: In order to know the feasibility of SBR granule applies for bitumen modifier, it researches the modified effects of SBR granule used as road bitumen ductility modifier and bitumen modifier through concoction and modified technology. It shows that the modified bitumen properties of SBR granule used as ductility modifier to make Tahe base oil road bitumen and as modifier to make modified bitumen are all accord with the index requirement of JTG F40-2004, and have high flash point, other properties almost same with bitumen make by block rubber. SBR used as ductility modifier as well as modifier. It has advantages of simple process and convenient to use.

Key words: SBR granule, road bitumen, modified bitumen, ductility modifier, modifier

Styrene-butadiene rubber (SBR) is not only the early and widely used bitumen modifier in the world, but also one of the earliest research bitumen modifiers in China. In general, the characteristics of SBR modified agent are significantly improve the modified bitumen low temperature ductility, increase viscoelastic properties, reduce the bitumen temperature sensitivity, and improve other performances. Therefore, the SBR application is behind the SBS in the polymer modified bitumen production all over the world.

At present, the marketed SBR can be divided into three types: solid rubber, rubber powder and liquid latex. Use SBR solid rubber to make bitumen modifier by solvent method, broken and other technologies. The disadvantage of solvent method is to make small SBR granule by using special machine. This process has low productive efficiency and higher investment for general companies. SBR powder is easy to use, but compared with the block rubber, it has low effective content. When use latex as bitumen modifier, whether premix technique or site mixing method, it also has water evaporation and not suitable for bitumen mass production. SBR granule appears for solve these disadvantages. In order to research the feasibility of this product applies for the bitumen modifier, Fushun Research Institute of Petroleum and Petrochemicals tests it. Test result shows that SBR granule can use as road bitumen ductility modifier and bitumen modifier.

Experiment part

1.1 Raw materials

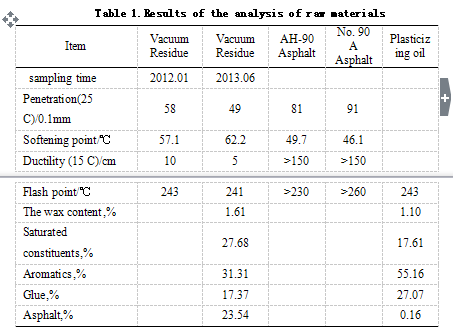

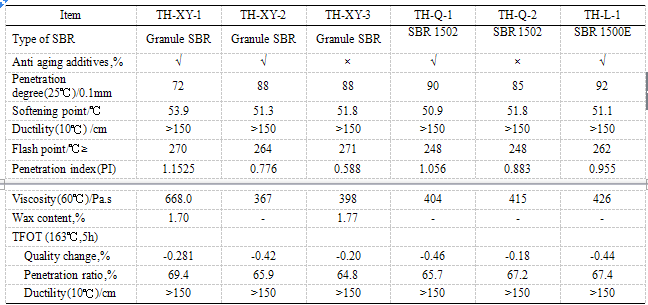

SBR granule is produce by Shandong Xianyuann Chemical Technology Co., Ltd. and use Q Company 1502, J Company 1500 and L company1500E block rubber as contrast modifier. Base bitumen is Tahe crude oil in different period made by TH Company, XA Company Tahe AH-90 bitumen and ZH Company Model 90 grade A bitumen. JM Company plasticized oil and Shandong company anti-aging additives. The test use basic properties of main raw material in Table 1.

1.2 technical requirement

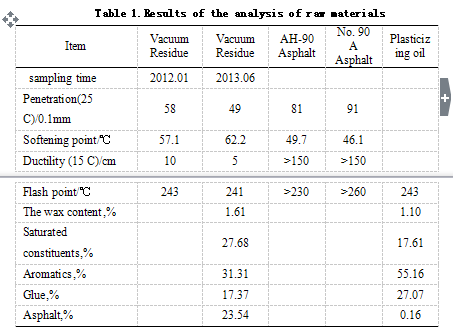

Use 90# Grade A and 70# Grade A road bitumen technical requirement of Transport Department JTG F40-2004 Technical Specification for Construction of Highway Bitumen Pavement [1]as road bitumen technical index( Table 2), and JTG F40-2004 polymer modified bitumen SBR(Ⅱ) technical requirement[2] as modified bitumen technical index(Table 3).

1.3 Experiment method

Adding three rubbers that mentioned before into plasticized to make base liquid by using high shear method. SBR concentration is 15% and SBR granule is calculate by 95% general rubber in base liquid.

According to a certain proportion, mix base liquid and residual oil to make road bitumen under 140℃~150℃.

According to a certain proportion, mix base liquid and residual oil or base bitumen to make modified bitumen under 150℃~160℃.

2 Results and Discussion

2.1 Test result of using as road bitumen ductility modifier

Adding appropriate ductility component to improve low temperature elongation, Anti-aging and other properties in Grade A road bitumen process for some raw materials. This paper uses SBR granule and block rubber as contrast test to observe it.

2.1.1 Analysis of base liquid preparation and properties

Study the viscosity temperature properties of base liquid that made by different SBR modifiers, Figure 1 is the graph. SBR granule base liquid viscosity less than 1502 and 1500 block base liquid, is goof for liquid delivery under the same effective rubber content condition.

2.1.2 Comparison of the Bitumen Properties

Figure 4 is bitumen properties that made by the same amount base liquid and different period Tahe crude oil. Data sheet shows the bitumen properties that made by different SBR base liquid and the Anti-aging agent effects on bitumen properties. Form the data, the obvious difference is bitumen that made by SBR granule base liquid has high flash point and low viscosity, but other index is almost the same. The properties of 70# and 90# bitumen are accord with Grade A index requirements.

2.1.3 long-term heat aging performance

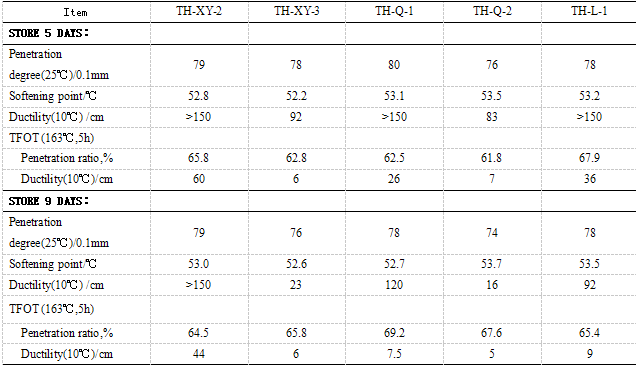

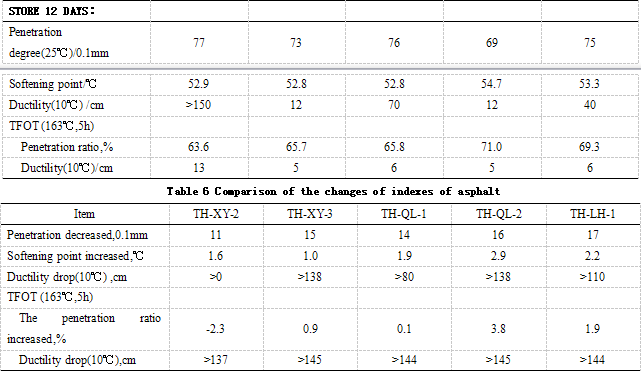

Table 4 in the No. 90 grade asphalt respectively into 4 containers each about 500g, in a constant temperature of 140 ℃ drying oven for the thermal storage. The properties of asphalt heat after storage in table 5. Thermal storage data changes after 12 days of bitumen index is shown in table 6.

After different time of heat storage, whether it is less penetration and extension, or softening point and needle ratio increased, granular SBR was lower than that of other two block glue that of SBR particles heat storage performance better than the other two pieces of plastic. In addition, adding anti - aging asphalt 10 DEG C extends to a greater degree, and anti aging asphalt 10 ℃ extension is obviously reduced, that anti aging agent on granular SBR effect more obvious, to improve the anti - aging performance of Tahe asphalt is more favorable.

2.2 Modified asphalt modifier feasibility study

SBR road asphalt modified is one of the modifier bitumen product. In recent years,the amount of that is increasing and with the SBR granule products coming,the asphalt modifier process become more and more convenient. In order to study the SBR granule to produce road asphalt products, provide the basis for the production of modified asphalt , do that serious test to get them applicably.

2.2.1 The SBR granule test results of modified asphalt.

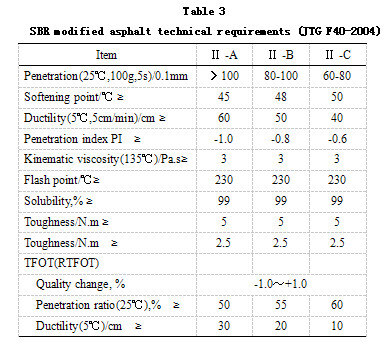

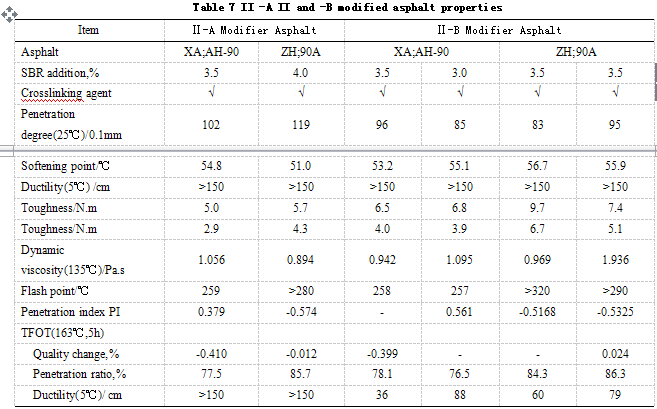

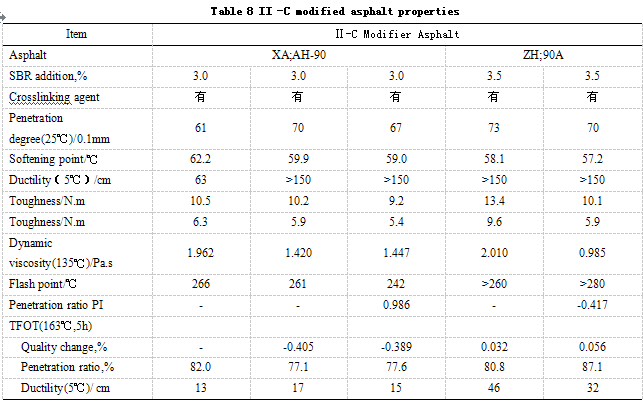

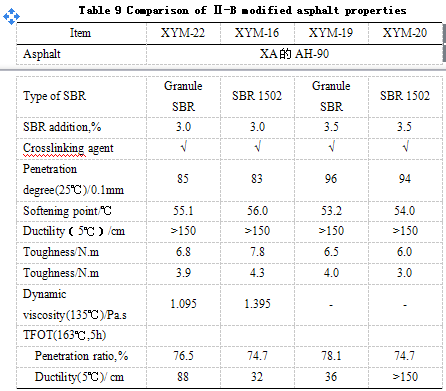

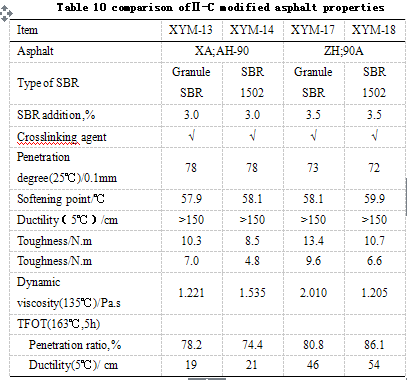

Table7 and table 8 are focus the asphalt modifier data about the Ⅱ-A、Ⅱ-B and Ⅱ-C.Test shows ,It can make the SBR modifier asphalt requirements of the JTG F40-2004 Ⅱ the XA;AH-90 and ZH;90A as the raw material, add the SBR granule and some crosslinking agent.

2.2.2 Compared with the SBR 1502 bulk

Table 9 and table 10 is the compare the SBR Granule with the SBR Bulk and get the test result.Those don’t have different for the modifier.

3.Conclusion

a) Xianyuan company produces granular SBR preparation of mother liquor and Tahe crude oil vacuum residue transfer of A-class No.90 and No. 70 A-class asphalt properties in full compliance with JTG F40-2004 technical index requirements. With the road asphalt from Tahe crude oil into commercial massive SBR than high flash point, other indicators are basically the same.

b) Thermal storage test results show that both penetration and ductility drop, or softening point and penetration ratio increased, SBR particles are shorter than the compared with rubber block, explicit element granular SBR heat storage performance is good in contrast with rubber block.

c) SBR granule as modifier , can be produced with the modified asphalt product requirements SBR index JTG F40-2004. The performance with the commercially available rubber modified asphalt.

d) SBR granule has the advantages of simple process, convenient production of asphalt, which can be used as the increased delay agent for the bitumen, also can be used for production of SBR modified asphalt modifier .

e) The other is not involved in the performance need to be further investigated.

Feasibility Study of Making Particulate SBR Used as Asphalt Modifier

Guo Jiaohe1 Liu Shuhua1 Ning Aimin1 Wang Tao2 Li Hongqiang2 Yao Dehong2

(1.Fushun Research Institute of Petroleum and Petrochemicals SINOPEC,Fushun 113001;

2.Shandong Xianyuan Chemical Technology Co.,Ltd.,Zibo 255400)

Abstract: In order to investigate feasibility of particulate SBR used as asphalt modifier, We studied the modified effect of the particulate SBR used as improving properties agent of paving asphalt and modified asphalt. The results showed that through out some appropriate process the quality level of Tahe oil paving asphalt and modified asphalt be improved by the particulate SBR satisfied the standard of JTG F40-2004. Compared with asphalt be improved by commercial lump SBR, this kind of asphalt be improved by the particulate SBR showd what the flash point index is higher, and other properties are similar to each other. The particulate SBR can be easy to use in paving asphalt and modified asphalt.

Key words: the particulate SBR; paving asphalt; modified asphalt; improve agent ;modifier