Application of SBR in Non-curing Rubber Bitumen Waterproofing Coating

Xu Li,Wang Tao

(Shandong Xianyuan Chemical Technology Co.,ltd., Zibo ,Shandong 255400,China )

Abstract: SBR is one of the main modifiers in non-curing rubber bitumen waterproofing coating. This paper introduces the SBR manufacturing method, and the SBR modified agent amount’s influence on heat resistance, low temperature performance, extension performance and viscosity of non-curing rubber modified bitumen waterproofing coating.

Key words: SBR, non-curing rubber modified bitumen waterproofing coating

Non-curing rubber bitumen waterproofing coating is one of the major application products that recommend by The Ten New Technologies of Building Industry (2010) of Ministry of Housing and Urban-Rural Development. It has environment-friendly property, 99% high solid content, non-curing permanent, magical healing, strong creep property, superior adhesion, and good compatibility with other membranes, therefore, gets the industry’s praise.

Non-curing rubber bitumen waterproof coating solves the waterproof layer break due to primary cracking stress, bending fatigue damage or premature aging cause by the waterproof layer in a high stress state and other issues, at the same time, it can well closed primary pores and cracks due to the viscosity of the coating, adapt to the complex construction operation to find the leakage parts automatically and repair damaged waterproof layer, solve the channeling problem of waterproof layer, improve waterproof reliability.

SBR in the non-curing rubber bitumen waterproofing coating can improve its low temperature performance, high temperature performance, creep performance. It’s one of the important modifiers of the non - curing rubber bitumen waterproof coating. This paper introduces SBR manufacturing method, and the effects of adding SBR modifier amount.

1.The experimental part

1.1Major raw materials

Bitumen: Zhonghai Bitumen (Taizhou) Co.,Ltd AH-90﹟ bitumen, the basic performance indicators are shown in table 1.

Rubber powder: Shanghai Lujiu Rubber & Plastic New Material Co.,Ltd. oblique tire activated rubber powder (80 meshes).

SBR: Shandong Xianyuan Chemical Technology Co., Ltd. GSQ-1XY-5, basic performance indicators are shown in table 2.

Softener: Ningbo Bohui Chemical Co., Ltd.

Special modifier: Xuzhou Zhibo Waterproofing Technology Co., Ltd.

Special additives: Xuzhou Zhibo Waterproofing Technology Co., Ltd.

Table 1: Zhonghai Bitumen (Taizhou) Co., Ltd AH-90 ﹟bitumen performance index

No. Item Index

1 penetration degree(25℃,5s,100g),0.1mm 92

2 Softening point (global method),℃ 45.2

3 10℃ Ductility,cm >150

4 60℃Dynamic viscosity,Pa.s 178

Table 2: Shandong Xianyuan Chemical Technology Co., Ltd. SBR performance index

No. Item Index

1 Appearance White powder

2 Particle size (mesh) 20

3 Moisture,% <2.5

4 Molecular weight 200 thousand ~ 300 thousand

5 Bd Sty % 21.5~35

6 Mooney viscosity ML+4 38~68

7 300% modulus Mpa 10~15

8 Tensile strength Mpa >21

9 Elongation at break % >320

1.2Test equipments and instruments

Laboratory high shear mixing emulsifier, MODEL L4RT, UK Silverson Machinery Company.

Motor stirrer, JJ-1, Jintan Medical Instrument Factory.

Low temperature freezer, DB-255LT, Qingdao Haier Special Electrical Appliance Co. ltd.

Loft drier, 101A-2, Shanghai Shen Guang Instrument Co., ltd.

Electronic tensile machine, CMT6104, Shenzhen xinsansi material detection Co Ltd.

Digital Viscometer, NDJ-5S, Shanghai Heng Ping Instrument Factory.

1.3Method of Non - curing Rubber Bitumen Waterproof Coating

When the bitumen temperature up to 140 ℃, put it into mixing tank, add softener, rubber powder, stirring about 30 minutes. The temperature rises to 160 ℃, uses high shear mixing machine to grind. Temperature up to 190 ℃, adding special modification agents and special additives, continue to grind 1 hour by high shear mixing machine. When cooling to 160 to 170 ℃, adding SBR and continue to use high shear mixing emulsification machine to grind for 1 hour, and add materials to stir for 1 hour. Finally, it will make rubberized bitumen non-curing waterproof coating. [1]

2 Results and discussion

The main raw materials of the non - curing rubber bitumen waterproof coating are SBR, waste tire powder, bitumen, special modifier and special additive. Special modifiers takes effect with SBR, waste tire rubber powder, carbon black, natural rubber, SBS and antioxidant interactions through special additives, it can form a stable chemical bond between bitumen and its molecule. This high polymer and bitumen will bring its superiority into full play under the stable state, therefore, improve the curing content, stability and performance. The addition amount of SBR directly affects the low temperature performance, elongation property and viscosity of the non-curing rubber bitumen waterproofing coating.

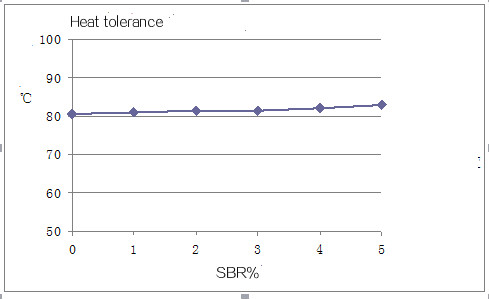

2.1 Effects of SBR on high temperature properties of non- curing rubber bitumen waterproofing coating

In the case of other raw material dosage unchanges, only change the amount of SBR, the amount of SBR added to the high temperature performance of the non-curing rubber bitumen waterproofing paint as shown in figure 1.

SBR%

Non-curing rubber bitumen waterproof coating heat resistance of specimen preparation and testing: the sample melt scraping to 120mm * 50mm * (2 ~ 4) mm aluminium, coated area is 100mm * 50mm, thickness of (2 + 0.2 mm), under standard test condition to set 24h. Put a 50mm short side and the lower part of a bracket contact, and horizontal plane into 45 degree angle into loft drier that have been heated to the required temperature, specimen and drying oven wall distance don’t less than 50mm, test center should be associated with the probe of the thermometer at the same horizontal position. Sample removes after 15min + 2H, then observes surface. Total 3 specimens were tested. Record the sample whether has sliding, flowing, dripping after the test finished.

From Figure 1 it shows that with the SBR amount increases, high temperature properties of non-curing rubber bitumen waterproof coating was essentially flat, probably because the heat resistance of the coating mainly cause by a special modifier in the special additives under the action of high temperature adsorption bitumen and its structure is similar to the saturation component. When the temperature is reduced, because the high melting point of special modifier, it is adsorbed and dissolved it saturated group points together gradually crystallized and precipitated so as to lock the these saturated oils, waxes components, present the lattice structure, so as to improve the degree of heat-resistant material, which has better heat stability. And SBR had little effects on heat tolerance.

2.2 Effects of SBR on low temperature properties of non- curing rubber bitumen waterproofing coating

In the case of other raw material dosage unchanges, only change the amount of SBR, the amount of SBR added to the non curing rubber bitumen waterproof coating low temperature performance of the table 3.

Table 3. Effects of the amount of SBR on the low temperature performance of the non-curing rubber bitumen waterproofing coating.

Idex SBR addition amount/%

0 1 2 3 4 5

low temperature performance/℃ -12 -16 -20 -23 -26 -30

Non-curing rubber bitumen waterproof coating low temperature properties of specimen preparation and testing: put the white hot melt sample on (100 x 100 mm (70 ~ 90 g / m2, thickness is (2 + 0.2 mm) and cut 3 pieces (100 x 25 mm) samples, after curing for 24 hours. The test pieces and the diameter are Phi 20mm round bars add has been adjusted to specified temperature under low temperature freezer, and then according to Chapter 13of GB / T 16777-2008 to test it, paint part outside when test. At the specified temperature for 1 hours, and then in the frozen liquid in the test piece around the round bar bending 180 degrees in 3 seconds, immediately pick up the sample and observe the surface with naked eye to find whether it has crack and fracture.

When the amount of SBR was zero, the low temperature performance of the non cured rubber bitumen waterproofing coating was -12℃, mainly due to the effects of rubber powder and special modifier. When the SBR adding amount is 6%, the low temperature performance reaches to -30℃. With the increase of the amount of SBR, the low temperature performance of the non-curing rubber bitumen waterproofing coating was improved obviously.

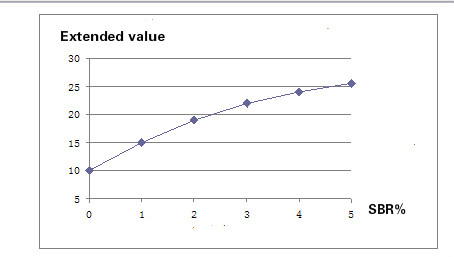

2.3 Effects of SBR on the elongation of non cured rubber bitumen waterproof coating.

In the case of other raw material dosage unchanges, only change the amount of SBR, the amount of SBR added to the non cured rubber bitumen waterproof coating extension performance (standard temperature) influence on the Table 4.

Non cured rubber bitumen waterproof coating extending properties of specimen preparation and testing: combine the two 120mm * 50mm * (2 ~ 4) mm plates with the short side, the gap between the two pieces of aluminum don’t more than 0.05mm, and the sample melt to an aluminum plate, the middle coated area of the two pieces of aluminum plate is 150mm * 50mm, thickness is (2 + 0.2 mm), total three samples and under standard test condition for curing for 24 hours. Put the sample in the middle of tensile machine and shall not be distorted, the recording this extension of pointer type ruler shown in numerical l0, start the tensile machine, drawing speed was 10mm / min, test pieces tension to split from the edge cracking or shrinking to 10 mm, the recording this extension ulnar finger needle shown in L1, accurate to 1mm.

When SBR modified non curing rubberized bitumen under load, SBR powder used in the formulation is styrene and butadiene that are random copolymers through low temperature emulsion polymerization, 1,2-poly butane content high, prone to molecular chain of slip, with non curable coating of bitumen with large deformation, so with the content of SBR increased non cured rubber bitumen waterproof coating elongation increases.

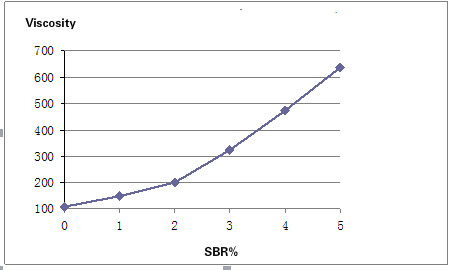

2.4 Effects of SBR on viscosity of non cured rubber bitumen waterproof coating

In the case of other raw material dosage unchanges, only change the amount of SBR, the amount of SBR added to the non cured rubber bitumen waterproof paint 165 degrees viscosity influence figure 5.

Figure 5 (unit of viscosity at 165℃: CPS)

It shows that when non-curing rubber bitumen waterproofing coating reaches to 165 ℃, the viscosity increases with the amount of SBR. On the one hand, because SBR molecules dispersed in bitumen mixture of physical entanglement of modified bitumen viscosity increase, on the other hand, SBR absorbs bitumen mixture oil to narrow the distance between bitumen, further more to change the viscosity. When the amount of SBR is larger, the viscosity changes will become more obviously with the adding amount. When the SBR addition reaches to 5%, spraying construction will became more difficult.

3. Conclusion

With the SBR amount increases, significantly enhance the low temperature properties of non-curing rubber bitumen waterproof coating; high temperature performance is essentially flat; extension performance enhancement. When the temperature reaches to 165℃, gradually increases the viscosity, liquidity weak. When SBR addition amount reaches to 5%, spraying construction becomes difficult. In a word, SBR amount has obvious effects on non-curing rubber bitumen waterproof coating, the addition amount is 2.5%, and the performance indicators reach even more than the industry standard The Non-curing Rubber Bitumen Waterproof Coating. But the amount added to a certain degree, the high viscosity is not conducive to the construction. Considering the actual production, construction and cost considerations, the SBR amount added should be moderate, the best amount is 2.5-3.5%.

Reference:

[1] Xu Li. Introduction of the Rubber Bitumen non-curing waterproof coating [J]. China Building Waterproof, 2010 (8) 4-6.

Introduction: Xu Li, male, born in 1974, senior engineer, mainly engaged in technology research and production of waterproof materials.

Tel: 13573337828,

E-mail:xuli5853155@126.com

The paper appeared in the China Building Waterproof 2015.10

Shandong Xianyuan Chemical Technology Co.,Ltd

Tel:86-0533-7210672

Fax:86-0533-7210672

Email:sdxianyuan@163.com