Basic knowledge of waterproofing

1. Durable life of waterproofing layer: refers to the period when the roof waterproofing layer can meet the requirements of normal use.

2. A waterproof fortification: a waterproof layer with separate waterproof capability.

3. Bituminous waterproofing roll material: base paper, fiber fabric, fiber felt is dipped with asphalt, and the surface is sprayed with powder, granular or sheet material to make curly sheet waterproofing material.

4. Polymer modified asphalt waterproofing roll material: using synthetic polymer modified asphalt as coating layer, fiber fabric or fiber felt as matrix, powder, granular, sheet or film material as cover material to make curly sheet waterproofing material.

5. Synthetic Polymer Waterproof Roll Material: Using synthetic rubber, synthetic resin or their blends as binder, adding appropriate chemical additives and fillers, etc., the sheet-like waterproof material can be curled by different processes, or the above-mentioned material can be combined with synthetic fibers to form two or more layers of sheet-like curling waterproof material.

6. Lengma emperor grease: Binder for cold asphalt made of petroleum asphalt, filler, solvent, etc.

7. Base treatment agent: In order to enhance the adhesion between waterproof material and base layer, pre-coating the coating on the base layer before the construction of the waterproof layer.

8. Lattice joints: In order to reduce cracks, pre-set joints on roof leveling layer, rigid waterproof layer and rigid protective layer. The rigid protective layer is only made into V-grooves on the surface, which is called surface partition slot.

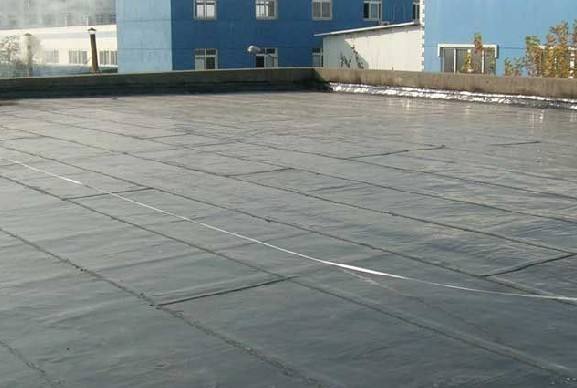

9. Full bonding method : When laying waterproof material, the construction method of full bonding between roll and base is adopted.

10. Empty laying method: When laying waterproofing membrane, the membrane and the base are bonded in a certain width around, while the rest are not bonded.

11. Strip sticking method: When laying waterproof membrane, the construction method of strip bonding between membrane and base is adopted. There are not less than two bonding surfaces between each sheet and the base, each of which has a width of not less than 150 mm.

12. Point bonding method: When laying waterproof rolls, the construction method of point bonding between rolls or perforated rolls and the base is adopted. There are not less than 5 points per square metre, and the area of each point is 100 mm x 100 mm. 13. Hot-melt method: The construction method of bonding hot-melt waterproofing membrane by melting the thermosol at the bottom of the hot-melt waterproofing membrane with flame heater.

14. Cold bonding method (cold construction): using adhesives or cold Mawang grease to bond the roll with the base, without heating construction method.

15. Self-adhesive method: The construction method of self-adhesive waterproof membrane is adopted, which does not need thermal construction or cementing material.

16. Hot air welding method: Hot air welding torch is used to bond waterproof rolled materials.

17. Asphalt-based waterproofing coating: an emulsion or solvent-based waterproofing coating based on asphalt.

18. Polymer modified asphalt waterproof coatings: water-emulsion or solvent-based waterproof coatings based on asphalt and modified by synthetic macromolecule polymers.

19. Synthetic Polymer Waterproof Coatings: A one-component or multi-component waterproof coating made of synthetic rubber or resin as the main film-forming material.

20.Matrix reinforcing material: refers to the chemical fibre non-woven fabric, glass fiber mesh fabric and other materials used for reinforcing the waterproof coating.

21. Modified asphalt sealant: Paste sealant made from asphalt as base material, modified by appropriate amount of synthetic macromolecule polymer, adding filler and other chemical additives.

22. Synthetic macromolecule sealing material: Paste sealing material, which is mainly made of synthetic macromolecule material and is processed by special production process, with appropriate chemical additives, fillers and colorants.

23. Joint displacement: In roof system, the change of joint clearance is caused by temperature and external force.

24. Tensile-compressive cyclicity: It reflects the sealing material's ability to keep seal after cyclic tension and compression cycles due to temperature change which causes joint displacement.

25.Backing Material: In order to control the insertion depth of sealing material and prevent the sealing material and the bottom of the seam from bonding, deformable material is arranged between the bottom of the seam and the sealing material.

26. Block rigid waterproofing layer: waterproof cement mortar infiltrated with waterproofing agent is used as the bottom waterproofing layer, and clay bricks and other fast materials are laid in the middle, then waterproofing cement mortar grouting and waterproofing surface layer is applied.

27. Overhead heat insulation roof: a thin product made of sintered clay or concrete, covering the roof waterproof layer and erecting a certain height of space, using air flow to speed up heat dissipation and play a role in heat insulation.

28. Storage roof: Store a certain height of water on the waterproof layer of the roof to insulate the roof.

29. Planting roof: Covering soil or laying loose materials such as sawdust and vermiculite on the waterproof layer of roof, and planting plants to insulate the roof.

30. Inverted roof: The roof with hydrophobic thermal insulation material on the waterproof layer.

31. profiled steel sheet: light roofing material made of galvanized steel sheet, rolled by forming machine, and coated with various anticorrosive and anticorrosive coatings and coloured baking varnish.