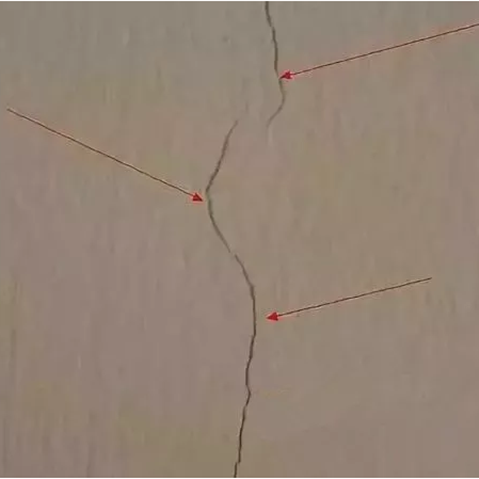

3. Cracks, internal and external corners and wall root are easy to appear after the construction of polymer cement waterproof coating

Cause analysis

① The construction environment temperature is too low, below 0 ℃, the coating water volatilizes slowly, and the freeze-thaw cycle is carried out alternately, which leads to the failure of film formation and cracks; or the temperature is too high in summer, which leads to the rapid water loss of the coating surface, inconsistent upper and lower shrinkage and cracks.

② During the construction, there is open water in the base course. If there is open water, the adhesion between the place and the base course is too thin to be penetrated and bonded with the base course.

③ Due to the too thick coating thickness, the inner layer of the internal and external corners and the wall root can not be dried completely due to the evaporation of water on the surface, the internal and external shrinkage of the material is inconsistent, and the inner layer of the water vapor volatilizes and impacts, resulting in small cracks on the surface.

④ During construction, water is added at will, resulting in unbalanced ratio, too small viscosity, flowing to the wall root, unable to fully solidify.

Solutions

① According to the requirements of JGJ 298-2013 for the environment temperature of waterproof indoor construction, 5 ℃ ~ 35 ℃, construction is prohibited if the environment temperature is not met.

② Strictly follow the mixing requirements of the instruction manual, and do not change the mixing ratio or add water to dilute at will.

③ All detailed joints shall be filleted. Before large-area painting, additional layers shall be made at pipe root, wall root and internal and external corners, and carcass reinforcement materials shall be added.

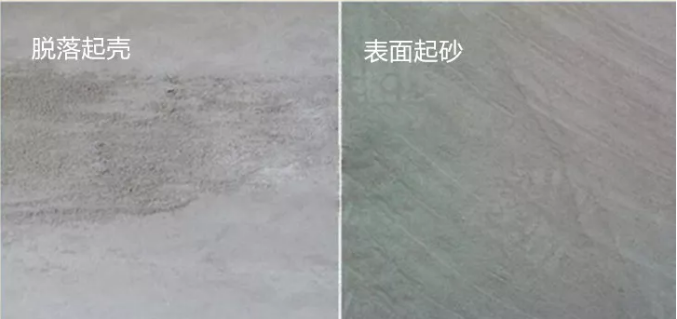

4. Sanding and shelling of cement-based permeable crystalline waterproof coating

Cause analysis

① If the base course is not treated, there are floating ash, floating sand, oil pollution and other conditions, the coating and the base course will fall off and peel off due to direct painting.

② Before the construction, the base course is dry and water deficient without wetting treatment, and the coating and the base course are peeled off due to direct painting.

③ The slurry is not prepared according to the required proportion, and too much water is added, resulting in shelling with the base.

④ The paint is not cured according to the curing requirements, resulting in sanding.

Solutions

① The base course shall be treated to be free of floating ash, sand and oil. If necessary, the base course shall be washed with steel brush and high-pressure water;

② Before construction, spray water to wet the construction base to make the base fully saturated but without open water;

③ Prepare the slurry according to the required proportion of the product, do not add too much water, and use the electric mixer to fully mix evenly

5. After the construction of emulsified spray coating, it will be exposed to the sun and blister

Cause analysis

① Brush type, one-time brush too thick, resulting in the internal moisture can not volatilize, but the surface film, the formation of drum.

② For spraying, component A and component B are not fully contacted during spraying, or the quantity of component B is insufficient.

③ Before the construction is completed and fully solidified, it is washed by rainwater, resulting in film formation damage, water absorption in the paint, and blistering after exposure.

Solutions

① Brush type, thin brush for many times, the first layer can be painted two layers after dry.

② Spray paint, adjust two nozzles of component A and component B, make them cross into fan, fully contact with demulsifier. Adjust the flow and spray in proportion.

(sourcing:net work)