Introduction

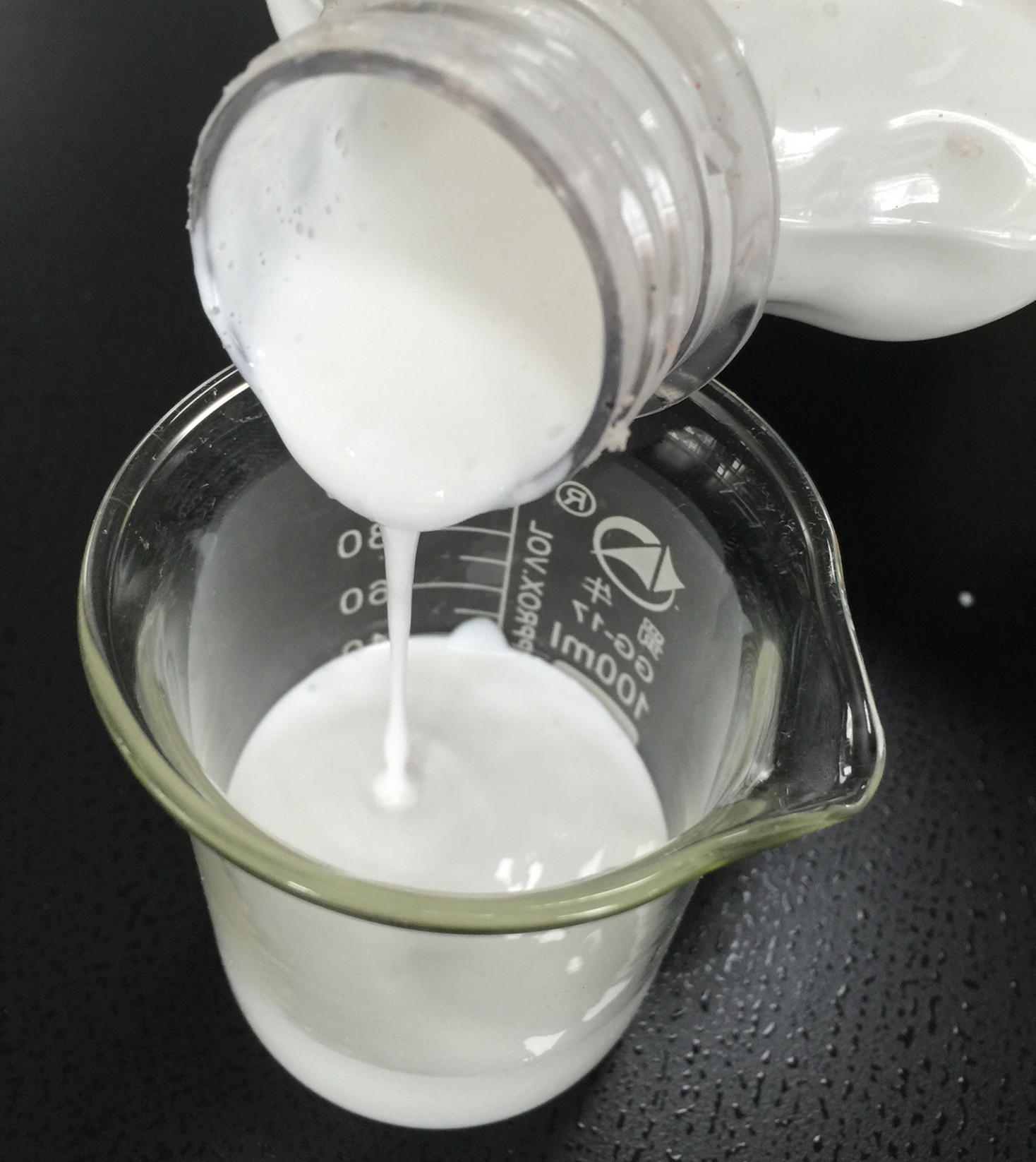

SBR is more formally known as Styrene Butadiene Rubber. It has an interesting chemistry, with different forms used for different purposes, but in the paving trade, it's most common use is to 'beef up' mortars and concretes. In our trade, it's most commonly used in its form as a thickish, gloopy white liquid, which echoes its roots as a synthetic latex.It is called styrene butadiene copolymer latex admixture, which is SBS latex. It is not 'pure' SBR, but a co-polymer which has been doctored and doped and diluted to give it the properties we need in the construction industry, that is designed as an integral adhesive for cement bond coats, mortars and concrete to improve bond strength and chemical resistance.

(elsewhere it is a major component of tyres and carpet backing amongst other things!)

Features & Benefits

When added to a standard mortar or concrete mix, SBR significantly enhances its adhesive strength. It makes mixes much harder, more resistant to abrasion, and it can make them more or less waterproof.

*Reduces cracking through increased mortar flexural strength

*Much reduced water:cement ratio improves strength and workability

*Reduced laitance in fresh mortars and concretes

*Reduced incidence of surface dusting on concrete floors and screeds

*Reduced susceptibility to salts/efflorescence

*Improved resistance to a wide range of common chemicals

*Improved resistance to damp and water vapour

*Improves bond strengths to hardened concrete

*Increases durability during freeze/thaw cycles

Surely there must be some drawbacks, otherwise we'd all be using it in everything we do, wouldn't we?

Well, the most important drawback, if that is the correct term, is that it significantly reduces the working life of a mortar or concrete. Whereas we might reasonably expect to have 30-40 minutes of working time with a standard mortar, when dosed with SBR, that is normally reduced to something more like 10-15 minutes. Consequently, a SBR-enhanced mortar or concrete needs using quickly. And it needs using cleanly!

Applications

SBR is a versatile product and it would be practically impossible to provide a comprehensive list of all its potential uses in the paving trade, but here are some of those more commonly encountered:

*As a strengthening agent for concrete surfaces Toppings, repairs, and leveling concrete surfaces

*General reconstruction work/latex modified overlays

*As a waterproofer for damp-susceptible paving stones

*Bridge decks, highways, and parking decks

*As a primer/bonding agent for wall cladding and step risers

Packaging

SBR Latex packed in 200L plastic bucket and each bucket net 200kg

Keep it clean

As already mentioned, but SBR mortar stuff sticks, so any spills, snots or splashes not cleaned up more or less immediately, could be there for quite some time. So,Wipe any spills immediately with copious amounts of clean water. Then wipe it again. Wear gloves and long sleeves. Don't pick yer nose! Clean your tools in water every few minutes.

Never, ever, ever leave a SBR mortar or concrete in the drum of a mixer. Once it's mixed, empty it out, flush out the drum, then flush it out again.

(sourcing:network)