*of Emulsified Asphalt

Emulsified asphalt is a liquid asphalt material formed by hot melting the base asphalt and mechanically dispersing it with fine asphalt particles in an aqueous solution containing an emulsifier. The emulsified particles of emulsified asphalt have a particle size of about 1 - 10um.Cationic emulsified asphalt is used in cement emulsified asphalt mortar for CRTSI slab ballastless track structure, and polymer is often used to modify asphalt in order to improve the elasticity, toughness and durability of cement emulsified asphalt mortar.

Emulsified asphalt can be modified in two ways: external mixing method and internal mixing method.The external mixing method is to prepare common emulsified asphalt first, then add a polymer latex modifier to the common emulsified asphalt, and mix and stir it. The polymer emulsions are usually CR emulsion, SBR emulsion, acrylic emulsion, etc.The internal mixing method is to mix polymers such as human rubber, plastics and other additives into hot asphalt, mix them evenly and react with asphalt to obtain polymer modified asphalt, and then produce modified asphalt emulsion through emulsification process. SBS is the polymer often used in the internal mixing method.

It is necessary to study the influence of modification methods on the performance of emulsified asphalt, mainly because emulsified asphalt is one of the important components of cement emulsified asphalt mortar, and its performance directly affects the performance of cement emulsified asphalt mortar.In this paper, the emulsified asphalt system was taken as the research object, and the influence of different modifier contents on the performance of SBR mixed with SBS modified emulsified asphalt was studied through experiments.

Test

Raw material

Using 70 # matrix asphalt, one is modified with SBS and then emulsified.The other one is emulsified first, then SBR latex is added into emulsified asphalt and stirred evenly.Emulsified asphalt is cationic and its solid content is controlled at about 60 %.

Test method

The tests of needle strength, softening point, ductility and Engler viscosity were carried out in accordance with JTGE 20 - 2011 Test Regulations for Highway Engineering Asphalt and Asphalt Mixture.

The average particle size was measured by a laser particle size analyzer. The average particle size refers to the volume average diameter.

Test results and analysis

Needle penetration

The needle penetration is an index for determining the consistency of asphalt. The smaller the needle penetration, the greater the consistency of asphalt.The value of human degree is decreased, and SBS doping is more decreased.With the increase of modifier content in ordinary milk, the needle value of emulsified asphalt residue decreased, and SBS content decreased more.The needle penetration of ordinary emulsified asphalt is 721 / 10 mm, the needle penetration of 4 % SBR is 681 / 10 mm, and the needle penetration of 4 % SBS is 591 / 10 mm ..The decrease of penetration value means that the consistency of asphalt after modification increases and SBS has a greater influence.

Softening point

Softening point can not only reflect the temperature sensitivity of asphalt, but also be a measure of its viscosity, and can also be used to evaluate the high-temperature stability of asphalt.The higher the softening point, the better the heat resistance of asphalt, that is, the better the temperature stability.The softening point of ordinary emulsified asphalt is 49 ℃, the softening point of 4 % SBR is 55 ℃, and the softening point of 4 % SBS is 60 ℃.With the increase of modifier content, the softening point of modified emulsified asphalt residue increases, and the softening point of SBS - doped asphalt is higher than that of SBR - doped asphalt.Due to the high molecular weight of the modifier, the average molecular weight of the modified asphalt is increased after being mixed with asphalt, and the macromolecule of the modifier plays a winding role in the asphalt, so the high temperature performance of the asphalt is enhanced.

Degree of ductility

The ductility reflects the softness of asphalt. The greater the ductility, the better the flexibility of asphalt.The ductility of ordinary emulsified asphalt at 5 ℃ is about 0 cm, that of 4 % SBR at 5 ℃ is 94 cm, and that of 4 % SBS at 5 ℃ is 32 cm.With the increase of modifier content, the 5 ℃ ductility of modified emulsified asphalt residues increases, and the 5 ℃ ductility of SBR blends increases even more.The low temperature ductility of emulsified asphalt is large, and the low temperature crack resistance of asphalt is improved.The molecular weight of the modifier is too different from that of asphalt, because asphalt is hard and the modifier is relatively soft at low temperature, the deformation and stretching of colloidal particles play an initial plasticizing role to a certain extent, reducing the brittleness of the whole material and improving the low temperature performance.Compared with SBS, SBR can significantly improve the low-temperature deformation ability of asphalt.

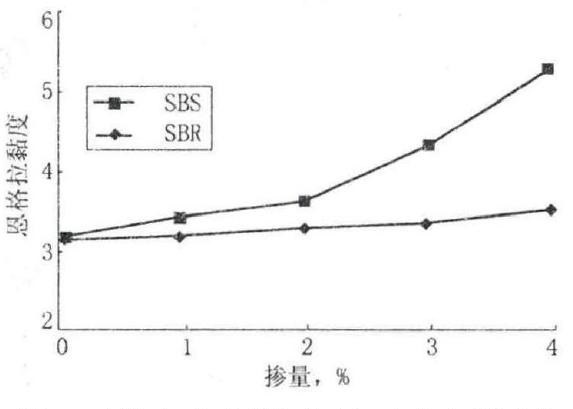

Engla viscosity

Engra viscosity is a commonly used index for evaluating asphalt performance, which represents the viscous state of emulsified asphalt and directly affects the construction and adhesion properties of modified emulsified asphalt.The viscosity of ordinary emulsified asphalt is 3.13, the Engla viscosity with 4 % SBR is 3.51, and the Engla viscosity with 4 % SBS is 5.3.With the increase of modifier content, the viscosity of modified emulsified asphalt increases, and SBS content has a great influence on the viscosity of emulsified asphalt.

Average grain diameter

The particle size of emulsified asphalt directly affects the stability and demulsification speed of emulsified asphalt emulsion.The average particle size of ordinary emulsified asphalt is 1.705 um, the average particle size of 4 % SBR is 1.432 um, and the average particle size of 4 % SBS is 5.213 um ..With the increase of SBS content, the average particle size of asphalt emulsion increases, while SBK content has little influence on the average particle size of emulsified asphalt.With the increase of SBS content, the emulsification difficulty of SBS modified asphalt increases, and the molecular weight of SBS is large. The average particle size after emulsification gradually increases with the increase of SBS content.

Conclusion

A ) With the increase of modifier content, the needle penetration of modified emulsified asphalt residue decreases and SBS content decreases more.

b ) With the increase of modifier content, the softening point of modified emulsified asphalt residue increases, and the increase of SBS content is larger.

C ) with the increase of modifier content, the 5 ℃ low temperature ductility of modified emulsified asphalt residue increases, and SBR can significantly increase the 5 ℃ low temperature ductility.

d ) With the increase of modifier content, the viscosity of modified emulsified asphalt increases, compared with SBR modified emulsified asphalt, the viscosity of SBS modified emulsified asphalt increases more obviously.

e ) With the increase of modifier content, the average particle size of SBS modified emulsified asphalt increases, while SBR has little influence on the average particle size.

(sourcing : network)