** Non-curing rubber bituminous waterproof coating and self-adhered waterproof membrane

1. Operating conditions

1) Remove debris, oil, sand, etc. on the surface of the base. Cleaning must be performed at any time during construction;

2) Patch grass-roots levelling ;

3) If there is clear water at the grassroots, it needs to be cleaned before construction;

4) Various embedded parts have been pre-installed and fixed.

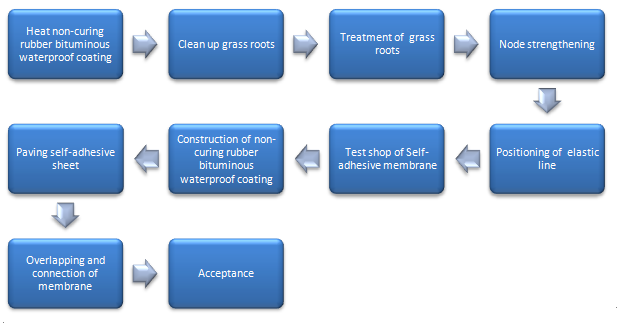

2. Process flow

3. Construction process

1) Heat non-curing rubber bituminous waterproof coating: The non-cured rubber bituminous coating is placed in a special heating device for heating, so that the paste-like rubber bituminous coating is completely melted into a fluid state for use.

2) Base shot blasting: Use a shot blasting machine to clean the laitance, sand, etc. of the base surface , so that the grass-roots level is solid and smooth. In the construction of the side wall, a sander is used to sand the ground.

3) Cleaning up the base: Clean the dust and debris on the surface of the base with tools such as brooms, shovels, etc., and keep the base surface flat. Uneven parts are to be repaired and leveled.

4) Base treatment: If necessary, brush the base treatment agent evenly on the grass-roots level so as not to have uncoated places or expose the bottom.

5) Strengthen the processing of nodes: The node parts (such as water fallout, pipeline through the floor, internal and external corner, etc.) are reinforced with fiberglass mesh cloth and non-curing rubber bituminous waterproof coating.

6) Positioning the elastic line: Conduct the elastic line in a grid pattern to determine the construction range of non-curing rubber bituminous waterproof coating. The width of each grid is 0.92m, the length is 5m, and the area is 4.6m2.

7) Test shop of self-adhesive membranes: spread the self-adhesive membrane naturally and loosely, place it according to the control line, and then roll up the membrane from both ends to the middle.

8) Construction of non-curing rubber bituminous waterproof coating:

①Scrape construction: The heated non-curing rubber bituminous waterproof coating is placed in a standard barrel and poured uniformly into the construction area ,ensure that the using amount of coating is 2.5 kg/m2. The non-cured rubber bituminous coating is scraped according to the range of the elastic line. Smearing thickness is evenly and does not reveal the bottom.

②spraying construction (upright surface): The heated non-curing rubber bituminous waterproof coating is loaded into a special spraying equipment, spraying construction is according to the pre-divided range, spray should be carried out twice in cross direction before and after spraying, to ensure the coating's dosage is 1.5kg/m2.

9) Laminated self-adhesive membrane: When the non-cured rubber bituminous coating is scratched, isolation film on the bottom surface of the self-adhesive membrane is removed at the same time , paste the membrane on the coating.

10) Overlapping and connection of membrane: Peel off isolation film on the overlapping edge of the self-adhesive membrane and connect the self-adhesive membranes. The non-curing rubber bituminous waterproofing coating is used for the internal and external sealing treatment on the T-junction of the overlapping membranes. Junctions of the membrane are sealed with non-curing rubber asphalt waterproof coating.

11) Sealing of edges: The edges of the facade membranes are pressed and fixed with nails, the spacing between the fasteners is not more than 250mm, and then use the non-curing rubber asphalt waterproof coating for sealing treatment.

(Sourcing: Website)