The origin of emulsified asphalt

To improve the adhesion between emulsified asphalt - aggregate interface, make the asphalt particles wrapped to the aggregate surface, water in the emulsion must be completely evaporated. In the case of water film, it is difficult to combine them with each other. The wrap of bitumen emulsion and aggregate is just simply adhesion. Adhesion between Asphalt and aggregate is low, if encountered wet or cold season in the construction, the evaporation of water in the emulsion is slow, the wrap time of asphalt around aggregate is extended, affecting the early formation of the road surface, thus delaying opening of traffic .

With the development of modern interface chemistry and colloid chemistry, cationic emulsified asphalt develops rapidly in recent years. This asphalt emulsion is to make the asphalt particles with cationic charge, when it contacts with the aggregate surface, the effect of opposite charges attraction leads to the adsorption of asphalt particles on the aggregate surface. Emulsion asphalt particles with a positive charge, and wet aggregate surface with negative charge, in the case of a water film, can still be adsorbed and combined. Thus, even in the wet or cold season (5 ℃ above), the cationic asphalt emulsion can still be applied as usual. As the cationic emulsified asphalt can enhance the adhesion with the aggregate surface , improve the early strength of the pavement, the pavement can be opened to traffic as soon as possible. Practices of road construction proved that: cationic emulsified asphalt plays the advantages of anionic emulsified asphalt, but also make up for its shortcomings. In this way, the development of emulsified asphalt has entered a new historical stage.

Application status of emulsified asphalt

At present, many countries in the world use large quantities of cationic emulsified asphalt to pave the road surface and grassroots on the low-traffic and high-traffic trunk lines. Especially in the maintenance of the old asphalt pavement, due to the simple construction, no need heating on the site, the amount of saving, the remarkable effect, cationic emulsified asphalt is welcomed by the maintenance constructors, thus the yield of cationic emulsified asphalt doubled.

Production of Modified emulsified asphalt

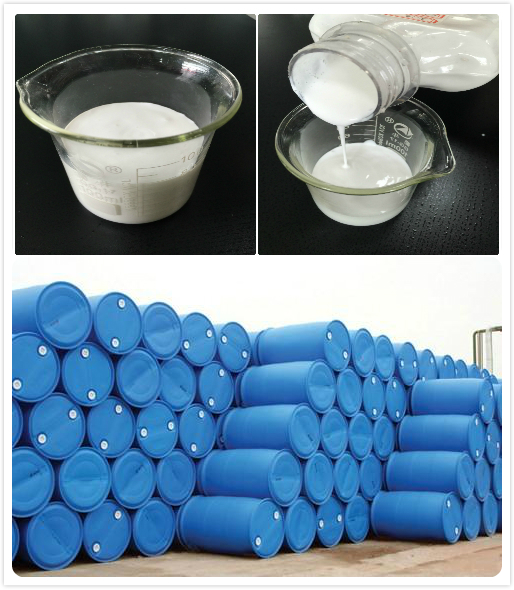

The so-called emulsified asphalt is to make the asphalt hot to flowing state (different heating bitumen has different heating temperature), and then by shearing, grinding and other mechanical action, makes the asphalt into fine particles and disperse in the emulsifier solution to form an oil-in-water, flowable dispersion systems at room temperature, also known as bitumen emulsions. Common dispersing equipments in domestic China include colloid mill, shears, Blender with blades, gear pump with nozzle and so on.

Emulsified asphalt firstly and then modified it

Make the hot asphalt and emulsion with a certain flow through the colloid mill together to produce ordinary emulsified asphalt, then add the latex modifier, through the role of mechanical stirring to disperse the latex and emulsified asphalt evenly, and make modified emulsified asphalt. The method has the advantages of less demanding on equipment, simple operation, the disadvantage of the single choice of modifier, only suitable for water-based latex, emulsion. Furthermore, it is difficult to disperse the latex and the emulsified asphalt evenly by simple mechanical agitation, which affects storage stability and use.

When emulsified asphalt, modified it simultaneously

Added the latex modifier and emulsifier to the soap tank at the same time, the production of modified emulsified asphalt method is currently a common process. The advantage is that the production process is the same as that of ordinary emulsified asphalt, and there is no need to modify the equipment. The disadvantage is that the addition amount of the modifier is limited, and the acid and alkali resistance of the modifier must be considered.

Modified asphalt firstly and then emulsified it

The modified asphalt is heated to a certain temperature, and used to produce the modified emulsified asphalt through a colloid mill together with the emulsion. In this method, the modified asphalt is usually heated to above 160 ° C, to increase the energy consumption, thus makes the discharge temperature of the emulsified asphalt to be too high. Equipment cooling system needs to be reformed ; its advantage is even distribution of particles after emulsification, and better storage stability.