* technology for SBR modified asphalt in Tibet

Introduction

Tibet has special natural conditions, such as high altitude, high cold, thin air, low oxygen content, low air pressure, large temperature difference between day and night, long sunshine time, strong ultraviolet rays, complicated climate types and short construction period. these characteristics put forward special requirements for the construction technology of Tibetan roads and the performance of road-building materials.Sbr modified asphalt is the preferred modified asphalt road material in Tibet.The main modifier used in SBR modified asphalt is styrene butadiene rubber, English name SBR, which is the initials of styrene butadiene rubber.Sbr modified asphalt has two major characteristics.

First, it has very good low temperature crack resistance. the ductility ( 5 ℃ ) of the original asphalt can reach 100 cm, and the ductility ( 5 ℃ ) of the residue after aging test can also reach 100 cm, which other asphalt cannot reach.Secondly, it has good viscosity and toughness, can effectively deal with asphalt shrinkage cracks and resist rutting problems caused by large temperature difference, and is a very good choice material for road construction.Sbr modified asphalt can be used in places with relatively bad conditions such as Tibet due to its good road performance.However, it is not simple to add SBR modifier to matrix asphalt to produce qualified SBR modified asphalt, which requires the performance of matrix asphalt, the adaptability of SBR modifier and the proportion of various additives.Therefore, it is necessary for us to make a series of analysis and research on SBR modified asphalt.

I. Analysis of raw material properties

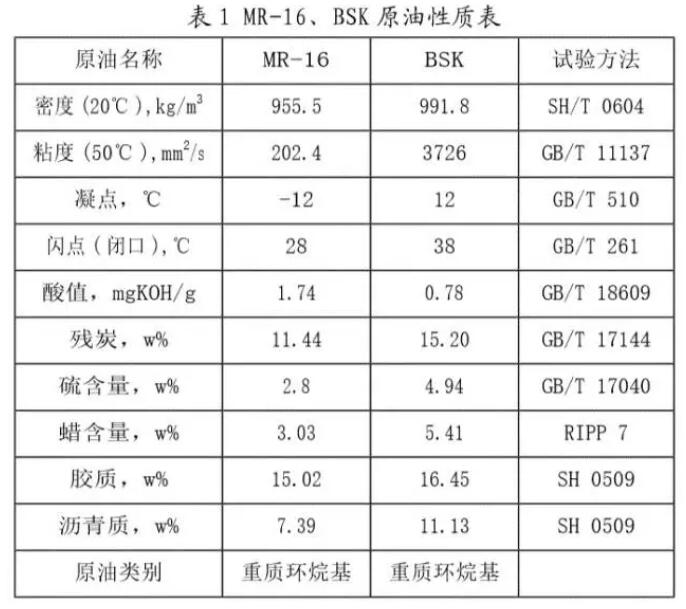

South American Mr - 16 and bsk belong to naphthenic base crude oil and are high quality raw materials for producing road petroleum asphalt. the properties of the two crude oils are shown in table 1.

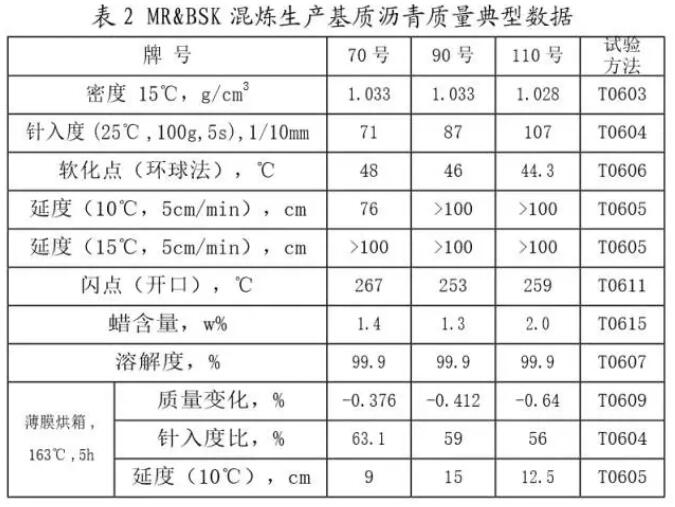

From the data in table 1, it can be seen that Mr - 16 and bsk crude oils have the characteristics of high density, high gum, high asphaltene content, low wax content, etc. they are high quality raw materials for producing matrix asphalt.Different grades of road asphalt products can be obtained by mixing Mr - 16 and bsk under reduced pressure distillation process. the process is simple, the cost is low, and the quality is excellent.The matrix asphalt data obtained by mixing the two crude oils are shown in table 2.

II. Selection of SBR modifier

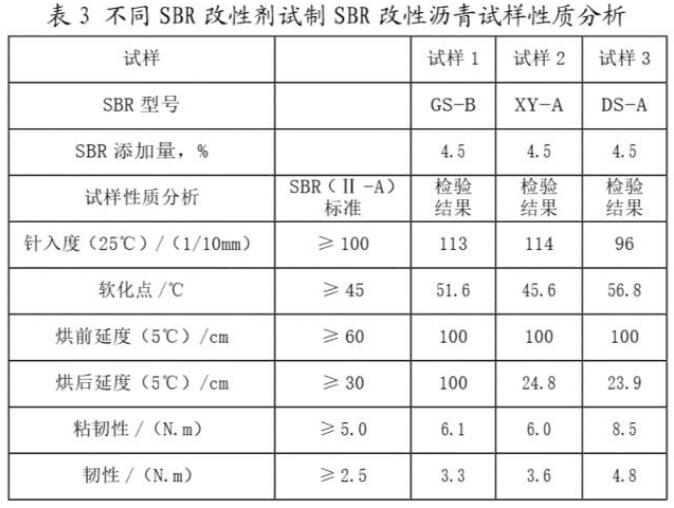

Three SBR modifiers produced by different manufacturers were selected.First, the device was simulated for a small test. under the same experimental conditions, one kind of SBR modifier was replaced at a time: GS - b type SBR modifier was group 1, xy - a type SBR modifier was group 2, and ds - a type SBR modifier was group 3.Then the three groups of samples were examined and analyzed.The result of that analysis are shown in table 3.

As can be seen from table 3, the analysis results obtained by the first group of samples are all qualified, and the quality data are higher than the standard of SBR modified asphalt ii - a of jtgf 40 - 2004 of the Ministry of communications. it is recommended to select the GS - b type SBR modifier used in the first group for subsequent experiments and trial production.

III. Optimization of matrix asphalt raw materials

Different grades of straight run asphalt obtained from south American Mr - 16 and bsk through distillation process were used as base asphalt, which was heated to 170 degrees, and a certain amount of rubber oil was added. then a certain proportion of GS - b SBR modifier was added. the shear rate was 4000 r / min, the shear rate was 30 minutes, and the temperature was controlled to 170 degrees.Then, stirring is developed, stirring speed is 300 r / min, stirring is carried out for 1 hour, and temperature is controlled at 170 degrees.The sample analysis data obtained are shown in table 4.

From the analysis and comparison of the data in table 4, it can be seen that No. 90 and No. 110 asphalt modified by Mr - 16 and bsk can all obtain qualified SBR modified asphalt products.However, the use of No. 90 asphalt as base asphalt material requires the addition of a relatively high proportion of compatilizer oil in order to meet the special requirement that the penetration of SBR modified asphalt is greater than 100. the use of No. 110 asphalt as base asphalt material can reduce the proportion of compatilizer oil to half.Theoretically, high penetration matrix asphalt can replace some rubber oil with some high aromatic hydrocarbon components.Therefore, the use of matrix asphalt with higher penetration will promote cost reduction and is more economical.Fourthly, the industrial trial production plan introduces 110 # asphalt with high penetration index produced by mixing south American Mr - 16 and bsk crude oil into a reaction kettle, adds a certain amount of rubber oil and a certain proportion of GS - b SBR modifier respectively, heats them to a suitable temperature and stirs them, cuts them through a colloid mill at a high speed, then uses a colloid pump to pump them into a finished product tank, stirs them for 2 hours, and finally obtains SBR ii - a, SBR ii - b and other products conforming to the jtgf 40 - 2004 standard of the Ministry of communications.

V. Optimization of packaging storage and transportation conditions

The long-term high temperature storage and transportation of SBR modified asphalt will cause serious deterioration of the quality of SBR modified asphalt, and it is not suitable for long-distance transportation of oil tanker vehicles due to its high viscosity.Especially for Tibetan areas with high cold and high altitude, the special environment will accelerate the aging of asphalt.In order to solve this problem, we have considered the special properties of SBR modified asphalt, that is, under the condition of normal temperature storage, the performance of SBR modified asphalt is stable, the product index is almost unchanged, and it can be stored for a long time.For this reason, the products are packaged and stored in the form of soft packages immediately after being produced, cooled to normal temperature to form solids, and then transported to Tibet in batches.Finally, the transportation conditions from production in the east to use in the west were met.

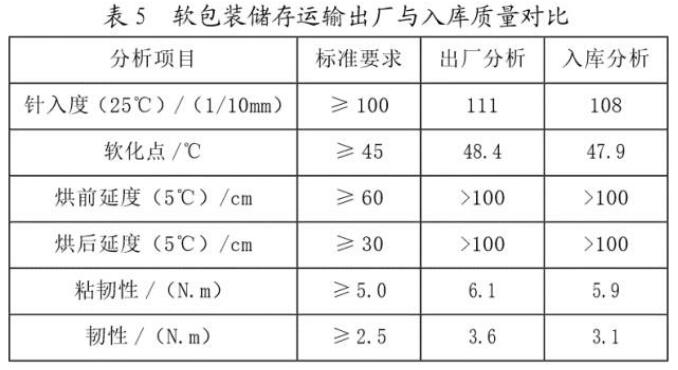

Judging from the two sets of data in table 5, the indicators of SBR modified asphalt products have not changed much after long-distance transportation in soft package.Thus, lowering the storage temperature of SBR modified asphalt can inhibit the aging or attenuation of SBR modified asphalt, thus effectively ensuring the quality of SBR modified asphalt products to be qualified and stable after long-distance transportation.

VI. Conclusion

1 ) South American Mr - 16 and bsk crude oils, due to their low wax content, high density and high gum and asphaltene content, can produce SBR modified asphalt products that meet the requirements of the Ministry of communications jtgf 40 - 2004 SBR modified asphalt ii - a standard through the atmospheric and vacuum distillation process.

2 ) Suitable SBR modifier can be selected through laboratory screening.

3 ) By increasing the penetration index of matrix asphalt, the proportion of compatibilizer oil can be appropriately reduced, thus reducing the production cost of SBR modified asphalt.

4 ) The storage and transportation mode of soft package at room temperature effectively restrains the aging and index attenuation of SBR modified asphalt products and ensures the quality of SBR modified asphalt products to be qualified and stable after long-distance transportation.

(sourcing: network)