◆ Introduction

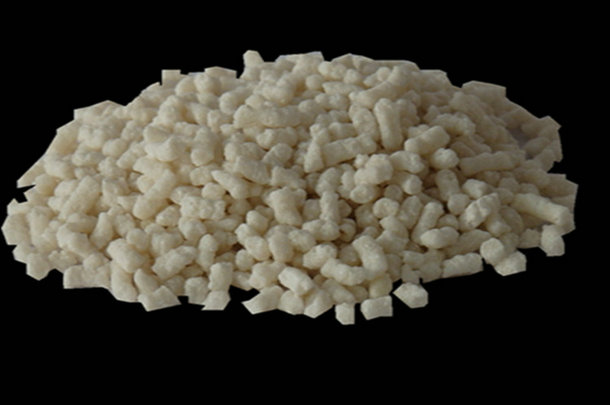

High ductility asphalt modifier is made of styrene and butadiene under low temperature (5℃), has 100% independent intellectual property, and it’s a high polymer elastic material which produces with other monomer based on the characteristics of road SBR ll modified asphalt. At present, the domestic production of SBR ll modified asphalt usually use rubber block or powder method, and this method has many problems such as complicated process, long time to swelling, fast decay after heat storage, etc. SBR high ductility asphalt modifier thoroughly changes the manufacturing status of domestic road SBR ll modified asphalt, compared with rubber block, it has many advantages of less amount, no cutting, short dissolving time and ageing resistance. Its internal performance and quality are better than domestic block styrene-butadiene rubber.