**waterproofing membrane

1.Coil waterproof bubble

Phenomenon

After the rolling material is put on, the bubble is found, generally from small to large, with the increase of temperature, the number and size of bubble increase.

Reason analysis:

At the grass-roots level is not dry, the surface is not sweep brush clean, waterproof layer at the bottom of the water vapor infiltration, surface without brushing treatment agent at the grass-roots level, binder and coil material mismatch, uneven coating, when the shop is stuck coil don't exclude the underside of the air, some of the exhaust slot plug, etc.

Precautions:

The base must be dry and ready to be laid after passing the test with a simple inspection method.

The base layer should be swept clean, and the selected base treatment agent and binder should match the material property of the coil material. After passing the test, it can be used.

When the coating primer is dry, brush the adhesive. When rolling, the air below must be removed and rolled tightly. It can also adopt 4 methods of slip-stick, point-stick and empty shop to ensure the smooth exhaust passage.

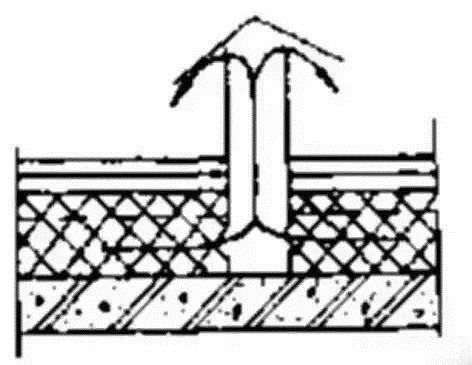

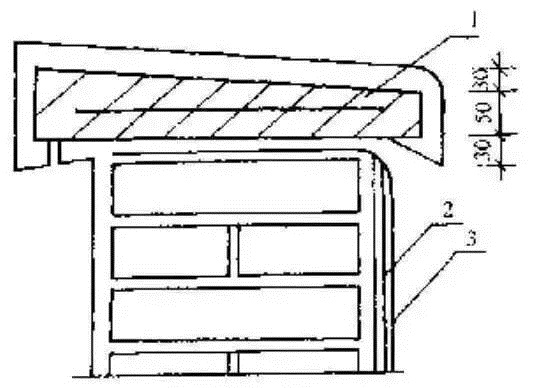

For the coils waterproof roof project with thermal insulation layer, the horizontal and horizontal exhaust grooves and the exhaust Wells of the waterproof layer must be installed, as shown in figure 1.

Figure 1 vent and discharge Wells

2.Coil waterproof layer crack

Phenomenon:

The waterproof layer presents cracks, joints and irregular cracks along the end of prefabricated roof panel.

Reason analysis:

Unintentionally used coiled material with low elongation, no additional buffer layer and reinforcing layer is used on the board end and the node detail, and construction method is wrong, such as being too tight when laying the roll.

Precautions:

1.It choose that coil material with high elongation and durability over 15 year.

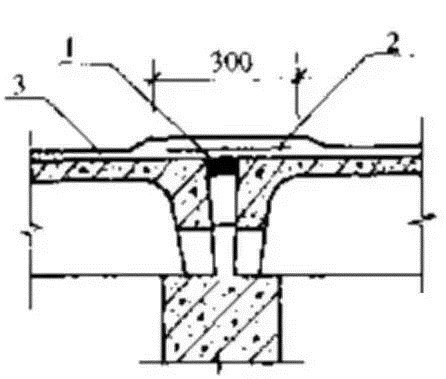

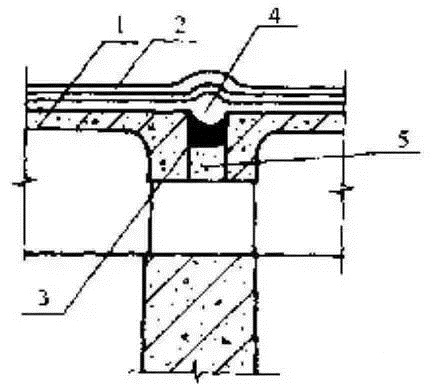

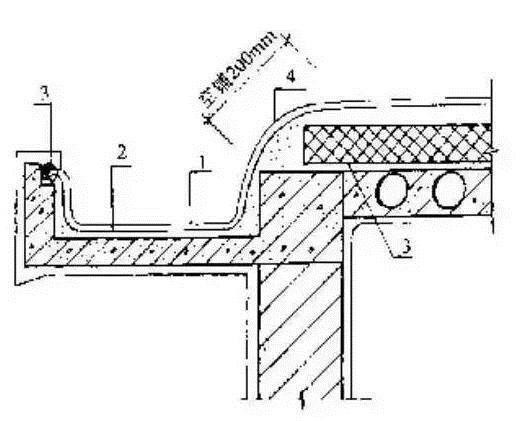

2.To set up a buffer layer at the end of the prefabricated roof, see Figure 2 and Figure 3, the dry top of the paper is 300mm. Don't pull the coils too tightly when laying them. Summer construction should be relaxed after paving.

3.When cracks appear in the waterproof roll, follow the regular crack bullet line and cut with the cutter. If the base layer does not leave a grid gap, the joint shall be slit, width shall be 20mm, the joint shall be filled with the soft sealing paste, the surface shall be buffered with a width of 200mm along the joint, then be filled with a thickness of 350mm wide of the waterproof layer of the coil material, and the treatment method of the node detail fracture shall be the same.

Figure 2 Seam buffer

1—Sealed material;2—Dry lay coil;

3—Waterproof layer

Figure 3 Seam treatment

1—The windward side is fixed;2—Dry lay the coils;

3—PVC cement;4—φ20 oil soaked straw rope;

5—C20 fine stone concrete

3.The roots of the parapet leak

Phenomenon:

The waterproof layer is hollowed and cracked along the root of parapet wall, masonry crack of parapet wall, pressure crack, mountain wall is pushed out of the wall, rain water is poured into the inner wall from the gap.

Reason analysis:

In the construction of leveling layer and rigid waterproof layer, the parapet wall is directly adjacent to the parapet wall without any grid joints. The masonry of long parapet wall has no expansion joints. The female child wall and other root Yin Angle did not make the circular arc according to the regulation, laid the roll material waterproof layer did not make the buffer layer according to the regulation, the end of the roll material end of the end of the head seal is not good, resulting in cracks, openings and leakage.

Precautions:

1、When building a flat surface and a rigid waterproof layer, you should leave a 30mm split between the women's walls and a flexible seal cream.

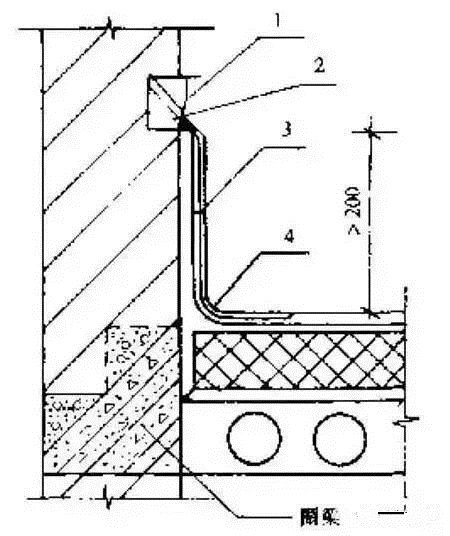

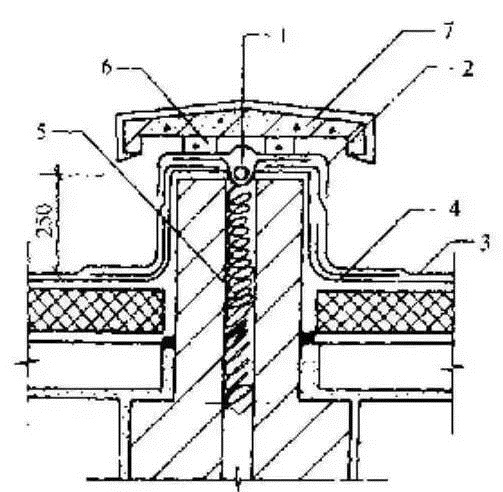

2、When the height of the parapet wall is greater than 800mm, grooves should be left, as shown in Figure 4. The end of the coil material should be cut and pressed into the reserved groove. After fastening, the groove should be filled with cement mortar or sealing materials.

3、When the height of the parapet wall is lower than 800mm, the end of the coil material is directly laid on the top of the parapet wall, and then the reinforced concrete compression roof is made. As shown in Figure 5.

Figure 4 Parapet wall coil floodwater collection

1—Groove;2—Sealed materials;

3—Additional layer;4—Waterproof layer

Figure 5 Parapet top and roll end

1—Coping;2—Additional layer;3—Waterproof layer

4.Gutter leakage

Phenomenon:

Cracks in roof and gutter intersections along the bottom of the trench or along the junction of the prefabricated eaves trench.

Reason analysis:

The structure deformation of tiangou and eaves ditch, the deformation of temperature difference leads to cracks, waterproof construction layer does not meet the requirements, the diameter of water falling cup is too small or blockage causes overflow and leakage.

Precautions:

1、Before the construction of the waterproof layer in the ditch, check whether the irrigation joints of the precast trench joints and roof base joints are strict and even. The shuiluo mugs should be installed well and the drainage slope should not be less than 1%.

2、The negative Angle at the bottom of the ditch should be applied into a circular arc, and the positive Angle at the corner should be applied into an obtuse Angle. The same quality coating film with the coil material should be used as a waterproof enhancement layer. As shown in Figure 6.

Figure 6 Gutter

1—Waterproof layer;2—Additional layer;3—Sealed materials;

4—Dry lay the coils

5.Deformation joint leaks

Phenomenon:

Leakage along the root crack of the deformation joint and the sealing part of the seam.

Reason analysis:

The details of the deformation joints are not properly constructed, there is no circular arc and waterproof additional layer at the root overcast Angle, and there is no cushioning layer on the top cover seal. After the opening of the cover, the damage results in leakage of the waterproof layer.

Precautions:

1、Check the quality of the plaster and the degree of drying, and clean the brush. As shown in Figure 7, lay an additional layer at the root, the additional coil material is 300mm wide, and the upper end of the coil material should be sticky (the rest is empty shop).

2、In vertical wall and top surface coil with paste, top of the wall cover a wide coil, with metope stick after good side, seam embedded in the pad material, the other side stick good again, top that covers a layer of coil, coil than on both sides of the wall 200 mm wide, covering cement, after using cast-in-place or precast reinforced concrete plate withhold, prefabricated plate seam fill dense embedded with sealant.

Figure 7 Deformation joint waterproof structure

1—Packing materials;2—Coil block;3—Waterproof layer;

4—Additional layer;5—Bituminous hemp;5—Cement mortar;

7—Concrete cover

6.Impinges mouth leak

Phenomenon:

Water is leaking around the water outlet, and some of the water outlet surface is higher than the waterproof layer, or because of the small water outlet, blockage and overflow.

Reason analysis:

Impinges koubei height is higher than the basic installation, impinges koubei contacts and structure layer without plugging embedded close-grained, horizontal type wall impinges mouth with wall body, the gap between without mortar filling embedded sealed, didn't do waterproof additional layer, waterproof layer, not into impinges koubei within a certain distance, the rain along the mouth impinges the lateral and cement mortar joint leakage.

Precautions:match

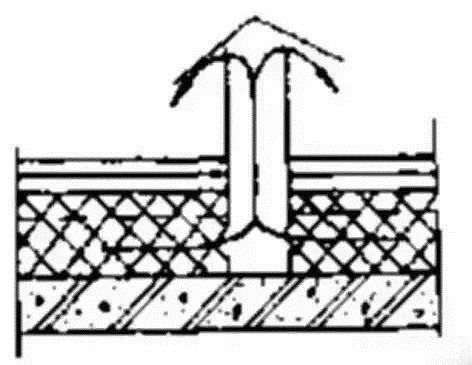

1、The straight water drop cup of pouring tiangou should be installed on the template before pouring concrete and compacting along the side of the cup. Precast gutter, after the installation of the sink cup to support the cup tube around the bottom template. With a mixture of 1:2:2 of cement, sand, fine stone concrete placing tamping, along the glass with the roof gutter attaches the upper left 20 mm x 20 mm groove filling sealing material, impinges koubei top surface should not be higher than gutter leveling layer. As shown in figure 8.

2、Additional coil impinges mouth paste method: cut a wide to or equal to 250 mm, length of impinges mouth diameter 100 mm coil rolled into a cylinder, into 100 mm impinges mouths stickup and firm, show impinges esrtuary coil cut into small article 30 mm wide rim, paste in impinges outlets around the plane, then cut a bigger than koubei impinges inner diameter 200 mm diameter of the coil, centered by impinges koubei diameter cut MiZiXing, glue stick, rice inside the note to his mouth down, and then the shop is stuck bedding face waterproof layer.

Figure 8 Impinges mouth

1—Sealed materials;2—Waterproof layer;3—Additional layer;

4—The leveling layer;5—Sealed materials

(sourcing: network)